-

運動控制器+軸卡

運動控制器+軸卡

-

步進/伺服驅動器

步進/伺服驅動器

-

伺服馬達

伺服馬達

步進馬達

音圈馬達

線性馬達

直驅馬達 -

回授元件

回授元件

光學尺

磁性尺

Linear Encoder

編碼器

顯示器 -

空氣軸承

空氣軸承

Air Bearing

Air conveyor -

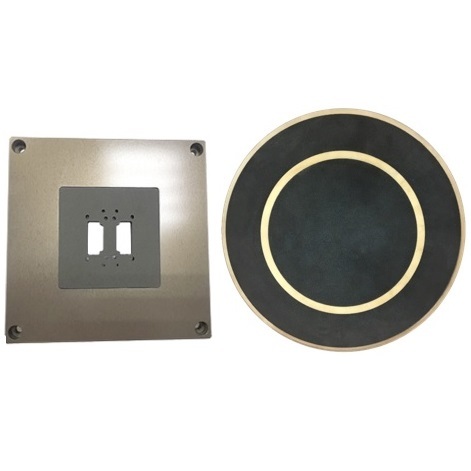

多孔性陶瓷真空吸盤

多孔性陶瓷真空吸盤

Porous Ceramic Chuck Table -

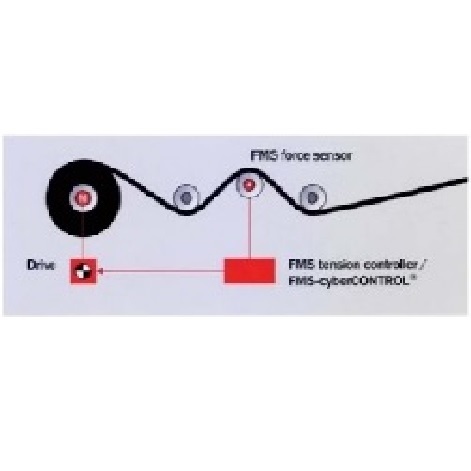

FMS 張力控制器

FMS 張力控制器

張力放大器

張力 sensor -

HarmonicDrive® 諧波減速機

HarmonicDrive® 諧波減速機

DirectDrive Motor 直驅電動機

Rotary Actuator 旋轉執行元件 -

減速機 / 齒輪齒排

減速機 / 齒輪齒排

-

聯軸器 / 免鍵式軸襯

聯軸器 / 免鍵式軸襯

-

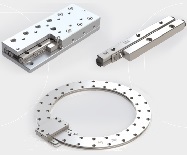

定位平台 (滑台) /

定位平台 (滑台) /

Stage / X-Y-Z Table

Theta Hybrid Hexapod

史都華平台 -

ALIO Hybrid Hexapod

ALIO Hybrid Hexapod

史都華平台 -

次系統設備(客製)

次系統設備(客製)

-

電動缸 / 千斤頂 /

電動缸 / 千斤頂 /

升降器 / 線性致動器 -

軸承 / 線性軸承 /

軸承 / 線性軸承 /

線性滑台 -

線性滑軌

線性滑軌

-

固態繼電器SSR

固態繼電器SSR

-

Karl Klein 鼓風機

Karl Klein 鼓風機

-

特殊環境用--

特殊環境用--

防爆、防水、

真空、低溫、重載 -

應用案例影片

應用案例影片

-

庫存出清

庫存出清

800-1513 & 800-1519

Control Modes

• Indexer, Point-to-Point, PVT

• Camming, Gearing, Position, Velocity, Torque

Command Interface

• Stepper commands

Single-ended or Differential selectable

• CANopen, DeviceNet

• ASCII and discrete I/O

• ±10V position/velocity/torque command

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

Communications

• CANopen/DeviceNet

• RS232

Feedback

• Digital Quad A/B encoder

• Secondary encoder / emulated encoder out

• Analog sin/cos encoder

• Digital Halls

I/O - Digital

• 12 inputs, 4 outputs

Accessories

• External regen resistors

• External edge filter

Dimensions: in [mm]

• 7.5 x 5.5 x 2.5 [191 x 140 x 64]

|

Model |

Vac |

Ic |

Ip |

|

800-1513 |

100 - 240 |

12 |

36 |

|

800-1519 |

100 - 240 |

6 |

18 |

description

The 800-1513/1519 combines CANopen networking with 100%

digital control of brushless or brush motors in an off-line powered

package that can operate from single or three-phase mains. These

models have stepper signal inputs that are programmable as either

single-ended or differential.

800-1513/1519 operates as a Motion Control Device under the

DSP-402 protocol of the CANopen DS-301 V4.01 (EN 50325-4)

application layer. DSP-402 modes supported include: Profile Position,

Profile Velocity, Profile Torque, Interpolated Position Mode (PVT),

and Homing .

Drive commissioning is fast and simple using CME 2™ software

operating under Windows® communicating with 800-1513/1519 via

CAN or an RS-232 link. CAN address selection is by a 16-position

rotary switch on the front panel. If there are more than fifteen

devices on a CAN bus, the additional address bits needed can

come from programmable inputs, or can be set in flash memory.

Profile Position Mode does a complete motion index on command

with S-curve acceleration & deceleration, top speed, and distance

programmable. In PVT mode, the controller sends out a sequence of

points each of which is an increment of a larger, more complex move

than a single index or profile. The drive then uses cubic polynomial

interpolation to “connect the dots” such that the motor reaches each

point (Position) at the specified velocity (Velocity) at the prescribed

time (Time). Homing mode is configurable to work with a variety

of limit, index, and home switches such that the drive moves the

motor into a position that has an absolute reference to some part

of the machine.

Nine logic inputs are programmable as limit or home switches,

stepper/encoder pulse inputs, reset, digital torque or velocity

reference, or motor-temperature. A tenth input is dedicated to

the drive Enable function. Three programmable logic outputs are

for reporting an drive fault or other status indications. A fourth

optically-isolated output can drive a motor brake from the external

+24 Vdc power supply or can be programmed as a logic output.

In addition to CANopen motion commands, 800-1513/1519 can

operate as a stand-alone drive. Current and velocity modes accept

±10 Vdc analog, digital 50% PWM or PWM/polarity inputs. In

position mode inputs can be incremental position commands from

step-motor controllers in Pulse/Direction or CW/CCW format, as

well as A/B quadrature commands from a master-encoder. Pulse

to position ratio is programmable for electronic gearing.

Power output of the drive varies with the input power which can

range from 100 to 240 Vac, and from 47 to 63 Hz. Either single or

three phase mains can be used giving 800-1513/1519 the ability

to work in the widest possible range of industrial settings. Signal

and control circuits are isolated from the high-voltage power supply

and inverter stage that connect to the mains. A +24 Vdc input

powers control circuits for keep-alive operation permitting the drive

power stage to be completely powered down without losing position

information, or communications with the control system.