-

運動控制器+軸卡

運動控制器+軸卡

-

步進/伺服驅動器

步進/伺服驅動器

-

伺服馬達

伺服馬達

步進馬達

音圈馬達

線性馬達

直驅馬達 -

回授元件

回授元件

光學尺

磁性尺

Linear Encoder

編碼器

顯示器 -

空氣軸承

空氣軸承

Air Bearing

Air conveyor -

多孔性陶瓷真空吸盤

多孔性陶瓷真空吸盤

Porous Ceramic Chuck Table -

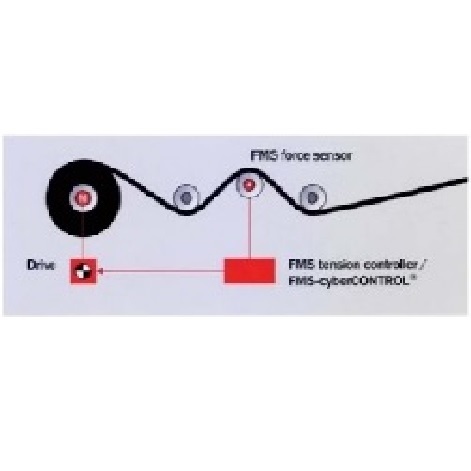

FMS 張力控制器

FMS 張力控制器

張力放大器

張力 sensor -

HarmonicDrive® 諧波減速機

HarmonicDrive® 諧波減速機

DirectDrive Motor 直驅電動機

Rotary Actuator 旋轉執行元件 -

減速機 / 齒輪齒排

減速機 / 齒輪齒排

-

聯軸器 / 免鍵式軸襯

聯軸器 / 免鍵式軸襯

-

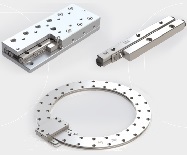

定位平台 (滑台) /

定位平台 (滑台) /

Stage / X-Y-Z Table

Theta Hybrid Hexapod

史都華平台 -

ALIO Hybrid Hexapod

ALIO Hybrid Hexapod

史都華平台 -

次系統設備(客製)

次系統設備(客製)

-

電動缸 / 千斤頂 /

電動缸 / 千斤頂 /

升降器 / 線性致動器 -

軸承 / 線性軸承 /

軸承 / 線性軸承 /

線性滑台 -

線性滑軌

線性滑軌

-

固態繼電器SSR

固態繼電器SSR

-

Karl Klein 鼓風機

Karl Klein 鼓風機

-

特殊環境用--

特殊環境用--

防爆、防水、

真空、低溫、重載 -

應用案例影片

應用案例影片

-

庫存出清

庫存出清

Stepnet 閉迴路步進驅動器 (STX、STP、STM、STL、SPM、SEM、SP2、SE2、TP2、TEL、TE2、SP4、SE4、R52)

|

PDF下載 |

||||||

|

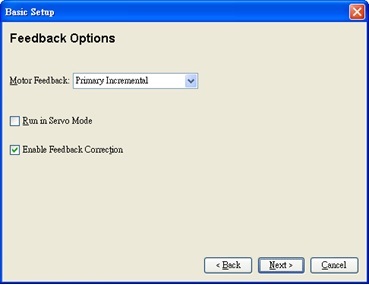

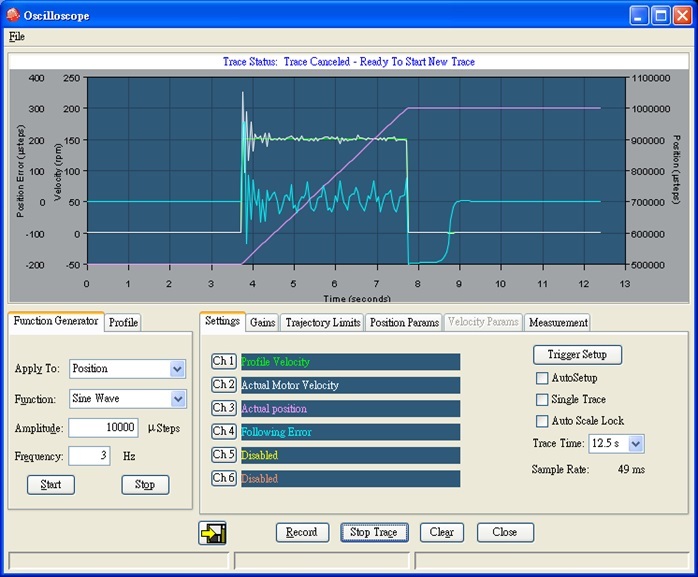

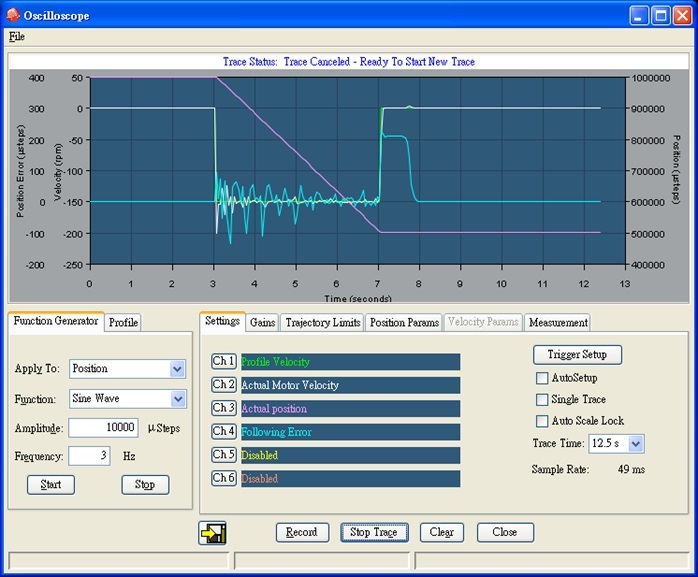

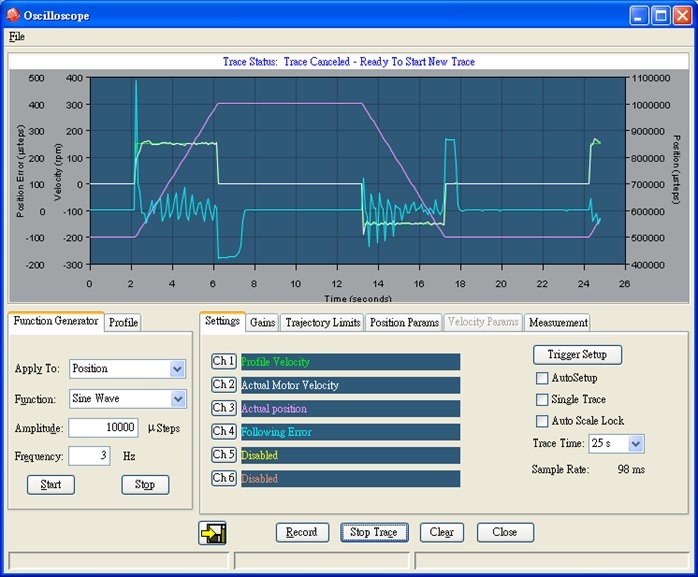

四、Stepnet閉迴路設定:

有兩種模式可選擇, 本次測試是使用修正

模式(Feedback Correction):

1、伺服模式(Servo Mode):

優點: 整定快

缺點: 靜止穩定性稍差

設定與調試較複雜

2、修正模式(Feedback Correction):

優點: 靜止穩定性佳

設定與調試較簡易

缺點: 整定較慢

|

|

Stepnet Panel

STP Panel

Control Modes

• Indexer, Point-to-Point, PVT

• Camming, Gearing

• Position, Velocity, Torque [Servo Mode]

• Position (Microstepping)

Command Interface

• CANopen

• ASCII and discrete I/O

• Stepper commands

• PWM velocity/torque command

• Master encoder [Gearing/Camming]

Communications

• CANopen

• RS-232

Feedback

• Digital Quad A/B encoder

I/O - Digital

• 12 inputs, 4 outputs

Dimensions: in [mm]

• 5.35 x 3.29 x 1.65 [135.9 x 83.5 x 41.8]

|

Model |

VDC |

IC |

IP |

|

STP-075-07 |

75 |

5 |

7 |

|

STP-075-10 |

75 |

10 |

10 |

DESCRIPTION

Stepnet is a stepping motor drive that combines CANopen

networking with 100% digital control of stepping motors. When

used with Copleys’ Accelnet™ and Xenus™ digital servo drives it

makes possible brushless, brush, and stepping motor control over

the same distributed network.

In Servo Mode, steppers fitted with encoders can be operated as

DC brushless servo motors in current, velocity or position modes.

This enables the motor to operate at higher RPM’s without stalling

which might occur in open-loop operation as a stepper.

Stepnet can operate as a stand-alone drive accepting incremental

position commands from step-motor controllers in Step/Direction

or CU/CD format, as well as A/B quadrature commands from a

master-encoder. Pulse to motor position ratio is programmable for

electronic gearing.

Set up is fast and simple using CME 2™ software operating under

Windows® and communicating with Stepnet via an RS-232 link.

CAN address selection is programmable in flash memory, by rotary

switch on the unit or via programmable digital inputs.

Stepnet operates as a Motion Control Device under the DSP-402

protocol of the CANopen DS-301 V4.01 (EN 50325-4) application

layer. DSP-402 modes supported include: Profile Position, Profile

Velocity, Interpolated Position Mode (PVT), and Homing Modes.

When operating in Servo Mode , Profile Torque mode is available.

The CAN bus interface is optically isolated from the drive circuits.

Profile Position mode does a complete motion index on command

with acceleration & deceleration, top speed, and distance

programmable.

In PVT (Position-Velocity-Time) mode, the controller sends out a

sequence of points each of which is an increment of a larger, more

complex move than that of a single index or profile. The drive

then uses cubic polynomial interpolation to “connect the dots”

such that the motor reaches each point (Position) at the specified

velocity (Velocity) at the prescribed time (Time). Homing mode is

configurable to work with a combination of limit and home switches

such that the drive moves the motor into a position that has an

absolute reference to some part of the machine. Profile Velocity

mode controls velocity, acceleration, and deceleration with no target

position defined.

There are twelve logic inputs. Input [IN1] is dedicated for drive

Enable. Eleven are programmable as limit or home switches,

stepper pulse inputs, A/B encoder, reset, CAN address, or motor

overtemperature sensor. There are four programmable logic outputs

for reporting a drive fault, operating a motor-mounted brake, or

other status indications. When operating as a node on a CANopen

network, the inputs and outputs can be read or controlled as

independent I/O points that are not linked to drive operation.

An Aux HV input is provided for “keep alive” power that preserves

the drive data (e.g. current position) and CANopen operation if +HV

has been removed as in an emergency-stop situation. This enables

the control system to monitor drive status and to enable an orderly

recovery without a full system reset, and homing of all axes.

Operation from transformer-isolated DC power supplies saves cost

in multi-axis systems.

Stepnet AC

STX

Control Modes

• Stand-alone: Pulse/Direction, CU/CD

• Indexer, Point-to-Point, PVT

• Master encoder (Gearing/Camming)

• Distributed driver (CANopen)

• Position, velocity, torque (Servo Mode)

Command Interface

• Step/Direction or CW/CCW inputs

• CANopen

• ASCII and discrete I/O

• ±10 Vdc velocity/torque (Servo Mode)

• PWM velocity/torque (Servo Mode)

• Digital inputs for indexer control

Communications

• CANopen

• RS232

Feedback

• Digital Quad A/B encoder

Differential or single-ended

• Secondary encoder / buffered encoder out

I/O - Digital

• 12 inputs, 4 outputs

Two high-speed inputs configurable as

differential or single-ended

Regen

• Internal

Dimensions: mm [in]

• 146 x 119 x 55 [5.73 x 4.7 x 2.17]

|

Model |

VAC |

IC |

IP |

|

STX-115-07 |

100-120 |

5 |

7 |

|

STX-230-07 |

200-240 |

5 |

7 |

Add “-H” to part number for factory-installed heatsink

DESCRIPTION

Stepnet AC is a compact, AC powered microstepping drive

for control of hybrid stepping motors. It operates as a

stand-alone driver taking Pulse/Direction or CW/CCW inputs

from an external controller or as a distributed drive on a

CANopen control network. In Servo mode a stepper with

encoder operates as a brushless servo motor in position,

velocity, or torque modes.

Indexing mode simplifies operation with PLC’s that use

outputs to select and launch indexes and inputs to read

back drive status. A single serial port on the PLC can send

ASCII data to multiple drives to change motion profiles as

machine requirements change.

CAN bus operation supports Profile Position, Profile Velocity,

Profile Torque, Interpolated Position, and Homing. Up to

127 Stepnet AC drives can operate on a single CAN bus

and groups of drives can be linked via the CAN so that they

execute motion profiles together.

Input command signals include ±10 Vdc (torque, velocity, in

Servo Mode), PWM/Polarity (torque, velocity in Servo Mode),

or Step/Direction and CU/CD (microstepping).

Separate ports are provided for differential or singleended

encoder connections. The active input is programmable.

Twelve digital inputs include a dedicated drive Enable,

motor overtemp switch, and 10 general purpose inputs.

Two of the high-speed inputs are programmable as differential

or single-ended.

Stepnet Module

STM Module

Control Modes

• Indexer, Point-to-Point, PVT

• Camming, Gearing

• Position, Velocity (Servo Mode)

• Position (Microstepping)

Command Interface

• CANopen

• ASCII and discrete I/O

• Stepper commands

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

• ±10V Position/Velocity/Torque command *

Communications

• CANopen

• RS-232

Feedback

• Digital Quad A/B encoder

I/O - Digital

• 12 inputs, 4 outputs

Dimensions: mm [in]

• 102 x 69 x 25 [4.0 x 2.7 x 1.0]

|

Model |

VDC |

IC |

IP |

|

STM-075-07 |

20-75 |

5 |

7 |

DESCRIPTION

Stepnet is a stepper motor drive that combines CANopen networking

with 100% digital control of stepper motors. When used with

Copley’s Accelnet™ and Xenus™ digital servo drives it enables

brushless, brush, and now stepper motors to be controlled over

the same distributed network.

In addition to CANopen motion commands, Stepnet can operate as

a stand-alone drive. Inputs can be incremental position commands

from controllers in Step/Direction or CU/CD format, as well as

A/B quadrature commands from a master-encoder. Step to motor

position ratio is programmable for electronic gearing.

The RoHS version has a ±10V analog input for position/velocity/

torque control. This enhances the ability of the driver to work

with external motion controllers which can control steppers using

Stepnet in servo-mode.

Set up is fast and simple using CME 2™ software operating under

Windows® and communicating with Stepnet via an RS-232 link.

CAN address selection is by digital inputs.

Stepnet operates as a Motion Control Device under the DSP-402

protocol of the CANopen DS-301 V4.01 (EN 50325-4) application

layer. DSP-402 modes supported include: Profile Position Mode,

Interpolated Position Mode (PVT), and Homing Mode.

Profile Position Mode does a complete motion index on command

with S-curve acceleration & deceleration, top speed, and distance

programmable. In PVT mode, the controller sends out a sequence

of points each of which is an increment of a larger, more complex

move than that of a single index or profile. The drive then uses cubic

polynomial interpolation to “connect the dots” such that the motor

reaches each point (Position) at the specified velocity (Velocity) at

the prescribed time (Time). Homing mode is configurable to work

with a combination of limit and home switches such that the drive

moves the motor into a position that has an absolute reference to

some part of the machine.

There are twelve logic inputs. Eleven are programmable as limit &

home switches, stepper pulse inputs, A/B encoder, reset, or motortemperature.

Another dedicated input is for drive Enable. There

are four programmable logic outputs for reporting a drive fault, or

other status indications.

An Aux HV input is provided for “keep alive” power that preserves

the drive data (e.g. current position) and CANopen operation if +HV

has been removed as in an emergency-stop situation. This enables

the control system to monitor drive status and to enable an orderly

recovery without a full system reset, and “homing” of all axes.

Operation from transformer-isolated DC power supplies saves cost

in multi-axis systems.

STL Micro Module

Control Modes

• Indexer, Point-to-Point, PVT

• Camming, Gearing

• Position, Velocity, Torque [Servo Mode]

• Position (Microstepping)

Command Interface

• CANopen

• ASCII and discrete I/O

• Stepper commands

• PWM velocity/torque command

• Master encoder [Gearing/Camming]

Communications

• CANopen

• RS-232

Feedback

• Digital Quad A/B encoder

I/O - Digital

• 12 inputs, 4 outputs

Dimensions: mm [in]

• 64 x 41 x16 [2.5 x 1.6 x 0.6]

|

Model |

VDC |

IC |

IP |

|

STL-055-04 |

55 |

3 |

4.5 |

|

STL-075-03 |

75 |

2 |

3 |

DESCRIPTION

Stepnet Micro Module is a stepper motor driver in a 4

in2 pc-board mounting package that combines CANopen

networking with 100% digital control of stepper motors.

Power output is compatible with most NEMA 17 and 23 size

stepper motors. The small footprint is well-suited for desktop

instrumentation and enables motor drive, interface, power

supply, and control circuits to be combined on a single PC

board.

Stepnet Micro Module can also operate as a stand-alone

driver taking incremental position commands from stepmotor

controllers in Step/Direction or CU/CD format, as well

as A/B quadrature commands from a master-encoder. Step

to motor position ratio is programmable for electronic

gearing.

When fitted with an incremental encoder a stepper motor

can be operated as a brushless servo motor using Stepnet

Micro Module’s Servo Mode feature, or as a conventional

stepper with stall detection.

Set up is fast and simple using CME 2™ software operating

under Windows® and communicating with Stepnet Micro

Module via an RS-232 link. CAN address selection is by

digital inputs or can be programmed into driver flash

memory.

As a CANopen node Stepnet Micro Module operates as a

Motion Control Device under the DSP-402 protocol of the

CANopen DS-301 V4.01 (EN 50325-4) application layer.

DSP-402 modes supported include: Profile Position, Profile

Velocity, Interpolated Position (PVT), and Homing. When in

Servo Mode, operating the stepper as a servo motor with

encoder feedback, Profile Torque mode is available.

Profile Position Mode does a complete motion index on

command with S-curve acceleration & deceleration, top

speed, and distance programmable. In PVT mode, the

controller sends out a sequence of points each of which

is an increment of a larger, more complex move than

that of a single index or profile. Profile Velocity mode has

acceleration, deceleration, and velocity control without a

position setpoint. Homing mode is configurable to work

with a combination of limit and home switches such that the

driver moves the motor into a position that has an absolute

reference to some part of the machine.

One logic input [IN1] is dedicated for the driver Enable

function. The other eleven are programmable as CAN

address, limit & home switches, stepper pulse inputs, A/B

master encoder, motor feedback encoder, reset, motion

abort, or motor-temperature. There are four programmable

logic outputs for reporting a driver fault, or other status

indications. When operating as a CAN node, inputs and

outputs can be used as general-purpose I/O with no link to

amplifier functions.

An Aux HV input is provided for “keep alive” power that

preserves the driver data (e.g. current position) and

CANopen operation if +HV has been removed as in an

emergency-stop situation. This enables the control system

to monitor drive status and to enable an orderly recovery

without a full system reset, and “homing” of all axes.

Operation from transformer-isolated DC power supplies

saves cost in multi-axis systems.

StepnetPLUS Module

SPM

Control Modes

• Position (Microstepping)

• Position/Velocity/Torque (Servo Mode)

• Indexer, Point-to-Point, PVT

• Camming, Gearing

Command Interface

• CANopen

• ASCII and discrete I/O

• Stepper commands

• ±10V or PWM velocity/torque (servo mode)

• Master encoder (Gearing/Camming)

Communications

• CANopen

• RS-232

Feedback

Incremental

• Digital quad A/B encoder

I/O

• Digital: 14 inputs, 6 outputs

• Analog: 1 input

Dimensions: mm [in]

• 76.3 x 58.2 x 20.5 [3.01 x 2.29 x 0.81]

|

Model |

VDC |

IC |

IP |

|

SPM-090-07 |

14-90 |

5 |

7 |

|

SPM-090-10 |

14-90 |

10 |

10 |

DESCRIPTION

Stepnet SPM is a high-performance, DC powered servo drive for

control of stepper motors via CANopen. The SPM operates as an

CANopen node using DSP-402 for motion control devices. Supported

modes include: Profile Position, Profile Velocity, Interpolated Position

Mode (PVT), and Homing.

With encoder feedback a stepper can be operated as a brushless

servo motor enabling ±10V analog or digital PWM velocity or torque

control in addition to CANopen. Direct position control from pulses

in CW/CCW, Pulse/Dir, or Quad A/B encoder format works in either

microstepping or servo modes.

Twelve high-speed digital inputs with programmable functions are

provided, and a lower-speed input for a motor temperature switch.

An SLI (Serial Peripheral Interface) function is supported by another

high-speed input and four high-speed digital outputs. If not used for

SLI, the input and outputs are programmable for other functions.

Two open-drain MOSFET can drive loads powered up to 24 Vdc.

An RS-232 serial port provides a connection to Copley’s CME2

software for commissioning, firmware upgrading, and saving

configurations to flash memory.

Drive power is transformer-isolated DC from regulated or

unregulated power supplies. An AuxHV input is provided for

“keep-alive” operation permitting the drive power stage to be

completely powered down without losing position information, or

communications with the control system.

SEM

Control Modes

• Indexer, Point-to-Point, PVT

• Camming, Gearing

• Position, Velocity, Torque (Servo Mode)

• Position (Microstepping)

Command Interface

• CAN application layer over EtherCAT (CoE)

• ASCII and discrete I/O

• Stepper commands

• ±10V Velocity/torque command (servo mode)

• PWM Velocity/torque command (servo mode)

• Master encoder (Gearing/Camming)

Communications

• EtherCAT

• RS-232

Feedback

Incremental

• Digital quad A/B encoder

I/O

• Digital: 14 inputs, 6 outputs

• Analog: 1 input

Dimensions: mm [in]

• 76.3 x 58.2 x 20.5 [3.01 x 2.29 x 0.81]

|

Model |

VDC |

IC |

IP |

|

SEM-090-07 |

14-90 |

5 |

7 |

|

SEM-090-10 |

14-90 |

10 |

10 |

DESCRIPTION

Stepnet SEM is a high-performance, DC powered drive for control of

stepper motors via EtherCAT, an Ethernet-based fieldbus. The SEM

operates as an EtherCAT slave using the CAN application layer over

EtherCAT (CoE). Supported modes include: Profile Position-Velocity,

Cyclic Synchronous Position-Velocity (CSP, CSV), Interpolated

Position Mode (PVT), and Homing.

With encoder feedback a stepper can be operated as a brushless

servo motor enabling ±10V analog or digital PWM velocity or torque

control in addition to EtherCAT. Direct position control from pulses

in CW/CCW, Pulse/Dir, or Quad A/B encoder format works in either

microstepping or servo modes.

Twelve high-speed digital inputs with programmable functions are

provided, and a lower-speed input for a motor temperature switch.

An SLI (Switch & LED Interface) function is supported by another

high-speed input and four high-speed digital outputs. If not used for

SLI, the input and outputs are programmable for other functions.

Two open-drain MOSFET outputs can drive loads powered up to

24 Vdc.

An RS-232 serial port provides a connection to Copley’s CME2

software for commissioning, firmware upgrading, and saving

configurations to flash memory.

Drive power is transformer-isolated DC from regulated or

unregulated power supplies. An AuxHV input is provided for

“keep-alive” operation permitting the drive power stage to be

completely powered down without losing position information, or

communications with the control system.

SP2

Control Modes

• Position (Microstepping)

• Position/Velocity/Torque (Servo Mode)

• Indexer, Point-to-Point, PVT

• Camming, Gearing

Command Interface

• CANopen

• ASCII and discrete I/O

• Stepper commands

• ±10V or PWM velocity/torque (servo mode)

• Master encoder (Gearing/Camming)

Communications

• CANopen

• RS-232

Feedback

• Digital quad A/B encoder

I/O

• Digital: 26 inputs, 7 outputs

• Analog: 2 inputs

Dimensions: mm [in]

• 114 x 73 x 21 [4.5 x 2.9 x 0.83]

|

Model |

VDC |

IC |

IP |

|

SP2-090-07 |

14-90 |

5 |

7 |

|

SP2-090-10 |

14-90 |

10 |

10 |

DESCRIPTION

Stepnet SP2 is a dual-axis, high-performance, DC powered drive

for position, and velocity control of stepper motors via CANopen.

Using advanced FPGA technology, the SP2 provides a significant

reduction in the cost per node in multi-axis CANopen systems.

Each of the two drives in the SP2 operate as CANopen nodes under

DSP-402 for motion control devices. Supported modes include:

Profile Position-Velocity, Interpolated Position Mode (PVT), and

Homing.

Servo mode allows ±10V analog position/velocity/torque, and

PWM velocity/torque control. Servo mode allows ±10V analog or

digital PWM control of position/velocity/torque. In microstepping

mode stepper command pulses and master encoder for camming

or gearing is supported.

Twenty-three high-speed digital inputs with programmable functions

are provided, and two low-speed inputs for motor temperature

switches.

An SLI (Switch & LED Interface) function is supported by another

high-speed input and four high-speed digital outputs. If not used for

SLI, the input and outputs are programmable for other functions.

Three open-drain MOSFET can drive loads powered up to 24 Vdc.

An RS-232 serial port provides a connection to Copley’s CME2

software for commissioning, firmware upgrading, and saving

configurations to flash memory.

Drive power is transformer-isolated DC from regulated or

unregulated power supplies. An AuxHV input is provided for

“keep-alive” operation permitting the drive power stage to be

completely powered down without losing position information, or

communications with the control system.

SE2

Control Modes

• Position (Microstepping)

• Position/Velocity/Torque (Servo Mode)

• Indexer, Point-to-Point, PVT

• Camming, Gearing

Command Interface

• CAN application layer over EtherCAT (CoE)

• ASCII and discrete I/O

• Stepper commands

• ±10V or PWM velocity/torque (servo mode)

• Master encoder (Gearing/Camming)

Communications

• EtherCAT

• RS-232

Feedback

• Digital quad A/B encoder

I/O

• Digital: 26 inputs, 7 outputs

• Analog: 2 inputs

Dimensions: mm [in]

• 114 x 73 x 21 [4.5 x 2.9 x 0.83]

|

Model |

VDC |

IC |

IP |

|

SE2-090-07 |

14-90 |

5 |

7 |

|

SE2-090-10 |

14-90 |

10 |

10 |

DESCRIPTION

Stepnet SE2 is a dual-axis, high-performance, DC powered drive for

position, velocity, and torque control of stepper motors via EtherCAT,

an Ethernet-based fieldbus. Using advanced FPGA technology, the

SE2 provides a significant reduction in the cost per node in multiaxis

EtherCAT systems.

Each of the two drives in the SE2 operate as an EtherCAT slave using

the CAN application layer over EtherCAT (CoE) protocol of DSP-

402 for motion control devices. Supported modes include: Profile

Position-Velocity, Cyclic Synchronous Position-Velocity, Interpolated

Position Mode (PVT), and Homing. Servo mode allows ±10V analog

or digital PWM control of position/velocity/torque. In microstepping

mode stepper command pulses and master encoder for camming

or gearing is supported.

Twenty-three high-speed digital inputs with programmable functions

are provided, and two low-speed inputs for motor temperature

switches.

An SLI (Switch & LED Interface) function is supported by another

high-speed input and four high-speed digital outputs. If not used for

SLI, the input and outputs are programmable for other functions.

Three open-drain MOSFET can drive loads powered up to 24 Vdc.

An RS-232 serial port provides a connection to Copley’s CME2

software for commissioning, firmware upgrading, and saving

configurations to flash memory.

Drive power is transformer-isolated DC from regulated or

unregulated power supplies. An AuxHV input is provided for

“keep-alive” operation permitting the drive power stage to be

completely powered down without losing position information, or

communications with the control system.

Control Modes

• Profile Position-Velocity-Torque, Interpolated Position, Homing

• Camming, Gearing

• Indexer

Command Interface

• CANopen

• ASCII and discrete I/O

• Master encoder (Gearing/Camming)

• Stepper mode position commands:

Digital: Pulse/Dir, CW/CCW, Quad A/B

Analog: ±10V position

• Servo mode commands:

Digital: Pulse/Dir, CW/CCW, Quad A/B

PWM velocity/torque command

Analog: ±10V position/velocity/torque

Communications

• CANopen

• RS-232

Feedback

Incremental Encoders

• Digital quad A/B

• Panasonic Incremental A Format

• Aux. quad A/B encoder / encoder

out Absolute Encoders

• EnDat, Absolute A

I/O Digital

• non-isolated, 8 isolated inputs,

• 5 isolated outputs, 2 non-isolated outputs

Analog

• 2 Reference Inputs, 12-bit

Safe Torque Off (STO)

• SIL 3, Category 3, PL d

Dimensions: IN [mm]

• 6.78 x 4.70 x 1.99 [172.1 x 119.3 x 50.4] no heatsink

• 6.78 x 4.70 x 3.14 [172.1 x 119.3 x 79.9] with heatsink

|

Model |

VDC |

IC |

IP |

|

TP2-090-07 |

90 |

5 |

7 |

|

TP2-090-10 |

90 |

10 |

10 |

Current ratings are for each axis

DESCRIPTION

Stepnet TP2 is a dual-axis, high-performance, DC powered drive for position

and velocity control of stepper motors via CANopen.

Using advanced FPGA technology, the TP2 provides a significant reduction in

the cost per node in multi-axis CANopen systems. Each of the two axes in the

TP2 operate as CANopen nodes under DSP-402 for motion control devices.

Supported modes include: Profile Position-Velocity, Interpolated Position Mode (PVT),

and Homing. In microstepping mode stepper command pulses and master encoder

for camming or gearing are supported.

Servo mode allows ±10V analog position/velocity/torque, and PWM velocity/torque control.

There are sixteen high-speed digital inputs, two low-speed inputs for motor temperature

switches, and eight optically isolated inputs. Outputs include five opto-isolated SSR and two

isolated brake outputs. All inputs and outputs have programmable functions.

An RS-232 serial port provides a connection to Copley’s CME2 software for commissioning,

firmware upgrading, and saving configurations to flash memory.

Drive power is transformer-isolated DC from regulated or unregulated power supplies.

An AuxHV input is provided for “keep-alive” operation enabling the drive PWM outputs

to be completely powered down without losing position information, or communications

with the control system.

Control Modes

• Microstepping Mode: Profile Position/Velocity, Interpolated Position, Homing

• Servo Mode: Cyclic Synchronous Position/Velocity/Torque

(CSP/CSV/CST)

• Camming, Gearing

• Indexer

Command Interface

• CANopen application protocol over EtherCAT (CoE)

• ASCII and discrete I/O

• Stepper commands

• ±10V position/velocity/torque

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

Communications

• EtherCAT

• RS-232

Feedback

Incremental Encoders

• Digital quad A/B/X

• Aux. quad A/B/X encoder Absolute Encoders

• EnDat, Sanyo Denki Absolute A

I/O Digital

• 6 High-speed inputs

• 1 Motor over-temp input

• 4 Opto-Isolated inputs

• 3 Opto-Isolated outputs

• 1 Opto-Isolated brake output

I/O Analog

• 1 Reference Input, 12-bit

Safe Torque Off (STO)

• SIL 3, Category 3, PL d

Dimensions: IN [mm]

• 5.08 x 3.41 x 1.99 [129 x 86.6 x 50.4]

• 5.08 x 3.41 x 3.39 [129 x 86.6 x 86.1] with heatsink

|

Model |

VDC |

IC |

IP |

|

TEL-090-07 |

90 |

5 |

7 |

|

TEL-090-10 |

90 |

10 |

10 |

DESCRIPTION

Stepnet Plus TEL is a high-performance DC powered microstepping drive for

control of hybrid stepping motors via EtherCAT using the CAN Application

protocol for EtherCAT (CoE). Microstepping modes are Profile Position,

Interpolated Position Mode (PVT), and Homing. With encoder feedback,

the TEL can operate a stepper as a brushless servo motor,

enabling Cyclic Sync Position/Velocity/ Torque operation.

As well as operating on EtherCAT networks, the TEL also supports the following

traditional control modes: step/direction, RS-232 ASCII, master encoder for

gearing and camming, digital input commands to initiate predetermined motion

sequences. Drive commissioning is fast and simple using CME 2™ software

operating under Windows® and communicating with the TEL via RS-232 or an

EtherCAT network. Feedback from incremental and absolute encoders is supported.

A multi-mode encoder port functions as an input or output depending on the drive’s

basic setup. As an input it takes feedback from a secondary encoder to create a

dual-loop position control system or as a master encoder for driving a cam table.

As an output, it buffers the digital encoder signals from the motor’s digital encoder

and eliminates split cables that would be needed to send the signals to both drive

and control system. There are seven non-isolated inputs and four opto-isolated

digital inputs that are bipolar types, sourcing or sinking current into a common

connection that can be tied to ground or +24V. [IN1] defaults to the drive Enable

function and is programmable to other functions. The other inputs are programmable.

All inputs have programmable active levels. Three opto-isolated outputs [OUT1~3]

have individual collector/emitter connections. An isolated MOSFET output [OUT4] is

programmable to drive a motor brake or other functions and has an internal flyback

diode for driving inductive loads. Drive power is transformer-isolated DC from regulated

or unregulated power supplies. An AuxHV input is provided for “keep-alive” operation

permitting the drive power stage to be completely powered down without losing position

information, or communications with the control system.

Control Modes

• Stepper mode: Cyclic Synchronous Position (CSP)

• Servo mode: Cyclic Synchronous Position/Velocity/Torque

(CSP, CSV, CST)

• Profile Position-Velocity-Torque, Interpolated Position, Homing

• Camming, Gearing

• Indexer

Command Interface

• CANopen application protocol over EtherCAT (CoE)

• ASCII and discrete I/O

• Master encoder (Gearing/Camming)

• Stepper mode position commands:

Digital: Pulse/Dir, CW/CCW, Quad A/B

Analog: ±10V position

• Servo mode commands:

Digital: Pulse/Dir, CW/CCW, Quad A/B

PWM velocity/torque command

Analog: ±10V position/velocity/torque

Communications

• EtherCAT

• RS-232

Feedback

Incremental Encoders

• Digital quad A/B

• Panasonic Incremental A Format

• Aux. quad A/B encoder / encoder out

Absolute Encoders

• EnDat, Absolute A

I/O Digital

• 24 non-isolated, 8 isolated inputs,

• 5 isolated outputs, 2 non-isolated outputs

Analog

• 2 Reference Inputs, 12-bit

Safe Torque Off (STO)

• SIL 3, Category 3, PL d

Dimensions: IN [mm]

• 6.78 x 4.70 x 1.99 [172.1 x 119.3 x 50.4] no heatsink

• 6.78 x 4.70 x 3.14 [172.1 x 119.3 x 79.9] with heatsink

|

Model |

VDC |

IC |

IP |

|

TE2-090-07 |

90 |

5 |

7 |

|

TE2-090-10 |

90 |

10 |

10 |

Current ratings are for each axis

DESCRIPTION

Stepnet Plus TE2 is a 2-axis, high-performance DC powered microstepping

drive for control of hybrid stepping motors via EtherCAT using the

CAN Application Layer for EtherCAT (CoE).

Microstepping modes are Profile Position, Interpolated Position Mode (PVT),

and Homing.

With encoder feedback, the TE2 can operate a stepper as a brushless servo motor,

enabling Cyclic Sync Position/ Velocity/Torque operation, too.

As well as operating on EtherCAT networks, the TE2 also operates in the following

traditional control modes: step/direction, RS-232 ASCII, master encoder for gearing

and camming, digital input commands to initiate predetermined motion sequences.

There are sixteen non-isolated inputs and eight opto-isolated digital inputs that are

bipolar types, sourcing or sinking current into a common connection that can be tied

to ground or +24V. [IN1&10] default to the drive Enable function for axes A & B,

and are programmable to other functions. The other inputs are programmable.

All inputs have programmable active levels.

Five opto-isolated outputs [OUT1~5] have individual collector/emitter connections.

Two MOSFET outputs [OUT6~7] are programmable to drive motor brakes or other

functions and have internal flyback diodes for driving inductive loads. Drive power is

transformer-isolated DC from regulated or unregulated power supplies.

An AuxHV input is provided for “keep-alive” operation permitting the drive power

stage to be completely powered down without losing position information,

or communications with the control system.

Control Modes

• Position (Microstepping)

• Position/Velocity/Torque (Servo Mode)

• Indexer, Point-to-Point, PVT

• Camming, Gearing

Command Interface

• CANopen

• ASCII and discrete I/O

• Stepper commands

• Master encoder (Gearing/Camming)

Communications

• CANopen

• RS-232

Feedback

• Digital quad A/B/X encoder

I/O Digital

• 24 HS inputs

• 8 MOSFET outputs

I/O SPI

• 1 HS input

• 4 HS outputs

Dimensions: mm [in]

• 101.6 x 76.2 x 20.83 [4.00 x 3.00 x 0.83]

|

Model |

VDC |

IC |

IP |

|

SP4-055-03 |

14-55 |

3 |

3 |

DESCRIPTION

Stepnet SP4 is a four-axis, high-performance, DC powered drive for position,

and velocity control of stepper motors via CANopen.

Using advanced FPGA technology, the SP4 provides a significant reduction in

the cost per node in multi-axis CANopen systems. Each of the four axes in the

SP4 operate as CANopen nodes under DSP-402 for motion control devices.

Supported modes include: Profile Position-Velocity, Interpolated Position Mode (PVT),

and Homing. Servo mode allows position/velocity/torque control.

Servo mode allows CANopen or digital PWM control of position/velocity/torque.

In microstepping mode stepper command pulses and master encoder for camming or

gearing is supported.

Twenty-four high-speed digital inputs with programmable functions are provided.

There are eight mosfet outputs that are 24V compatible.

An SPI port is provided with one high-speed input and four high-speed digital outputs.

If not used for SPI, the input and outputs are programmable for other functions.

An RS-232 serial port provides a connection to Copley’s CME2 software for commissioning,

firmware upgrading, and saving configurations to flash memory.

The CANopen port is optically isolated.

Drive power is transformer-isolated DC from regulated or unregulated power supplies.

An AuxHV input is provided for “keep-alive” operation permitting the drive power stage to

be completely powered down without losing position information, or communications with

the control system.

Control Modes

• Cyclic Synchronous Position/Velocity (CSP, CSV in servo mode)

• Profile Position/Velocity, Interpolated Position, Homing

• Position: Digital Inputs

• Indexer, Point-to-Point, PVT

• Camming, Gearing

Command Interface

• CANopen application protocol over EtherCAT (CoE)

• ASCII and discrete I/O

• Stepper commands

• PWM velocity command

• Master encoder (Gearing/Camming)

Communications

• EtherCAT

• RS-232

Feedback

• Digital quad A/B/X encoder

I/O Digital

• 24 HS inputs

• 8 MOSFET outputs

I/O SPI

• 1 HS input

• 4 HS outputs

Dimensions: mm [in]

• 101.6 x 76.2 x 20.83 [4.00 x 3.00 x 0.83]

|

Model |

VDC |

IC |

IP |

|

SE4-055-03 |

14-55 |

3 |

3 |

DESCRIPTION

Stepnet SE4 is a four-axis, high-performance, DC powered drive for position,

velocity, and torque control of stepper motors via EtherCAT, an EtherNET-based fieldbus.

Using advanced FPGA technology, the SE4 provides a significant reduction in the cost per

node in multiaxis EtherCAT systems. Each of the four drives in the SE4 operates as an

EtherCAT slave using the CAN Application protocol over EtherCAT (CoE) of CiA402 for motion

control devices. Supported modes include: Cyclic Synchronous Position-Velocity,

Profile Position-Velocity, Interpolated Position Mode (PVT), and Homing.

Servo mode provides digital PWM control of position/velocity/torque.

In microstepping mode stepper command pulses and master encoder for camming

or gearing is supported. Twenty-four high-speed digital inputs with programmable

functions are provided. There are eight mosfet outputs that are 24V compatible.

An SLI (Switch & LED Interface) function is supported by another high-speed input and

four high-speed digital outputs. If not used for SLI, the input and outputs are programmable

for other functions. Eight open-drain MOSFET can drive loads powered up to 24 Vdc.

An RS-232 serial port provides a connection to Copley’s CME2 software for commissioning,

firmware upgrading, and saving configurations to flash memory.

The EtherCAT port is magnetically isolated. Drive power is transformer-isolated DC from

regulated or unregulated power supplies. An AuxHV input is provided for “keep-alive”

operation permitting the drive power stage to be completely powered down without

losing position information, or communications with the control system.

Control Modes

• Position (Microstepping)

• Position/Velocity/Torque (Servo Mode)

• Indexer, Point-to-Point, PVT

• Camming, Gearing

Command Interface

• CANopen

• ASCII and discrete I/O

• Stepper commands

• ±10V or PWM velocity/torque (servo mode)

• Master encoder (Gearing/Camming)

Communications

• CANopen

• RS-232

Feedback

Incremental

• Digital quad A/B encoder

I/O

• Digital: 14 inputs, 6 outputs

• Analog: 1 input

Dimensions: mm [in]

• 76.3 x 58.2 x 20.5

[3.01 x 2.29 x 0.81]

|

Model |

VDC |

IC |

IP |

|

R52-090-07 |

14-90 |

5 |

7 |

|

R52-090-10 |

14-90 |

10 |

10 |

DESCRIPTION

Stepnet R52 is a high-performance, DC powered driver for control of stepper

motors via CANopen. The R52 operates as an CANopen node using DSP-402

for motion control devices. Supported modes include: Profile Position,

Profile Velocity, Interpolated Position Mode (PVT), and Homing.

With encoder feedback a stepper can be operated as a brushless servo motor

enabling ±10V analog or digital PWM velocity or torque control in addition to CANopen.

Direct position control from pulses in CW/CCW, Pulse/Dir, or Quad A/B encoder

format works in either microstepping or servo modes. Twelve high-speed digital

inputs with programmable functions are provided, and a lowerspeed input for a

motor temperature switch. An SLI (Serial Peripheral Interface) function is supported

by another high-speed input and four high-speed digital outputs. If not used for SLI,

the input and outputs are programmable for other functions. Two open-drain MOSFET

can drive loads powered up to 24 Vdc. An RS-232 serial port provides a connection to

Copley’s CME2 software for commissioning, firmware upgrading, and saving configurations

to flash memory.

Drive power is transformer-isolated DC from regulated or unregulated power supplies.

An AuxHV input is provided for “keep-alive” operation permitting the drive power stage

to be completely powered down without losing position information, or communications

with the control system.

資料來源: https://www.copleycontrols.com/wp-content/uploads/2018/02/R52_DS.pdf