-

運動控制器+軸卡

運動控制器+軸卡

-

步進/伺服驅動器

步進/伺服驅動器

-

伺服馬達

伺服馬達

步進馬達

音圈馬達

線性馬達

直驅馬達 -

回授元件

回授元件

光學尺

磁性尺

Linear Encoder

編碼器

顯示器 -

空氣軸承

空氣軸承

Air Bearing

Air conveyor -

多孔性陶瓷真空吸盤

多孔性陶瓷真空吸盤

Porous Ceramic Chuck Table -

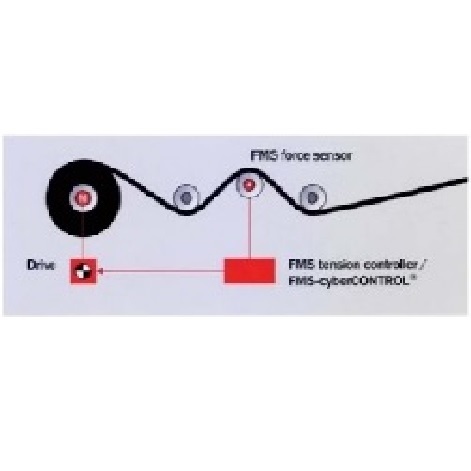

FMS 張力控制器

FMS 張力控制器

張力放大器

張力 sensor -

HarmonicDrive® 諧波減速機

HarmonicDrive® 諧波減速機

DirectDrive Motor 直驅電動機

Rotary Actuator 旋轉執行元件 -

減速機 / 齒輪齒排

減速機 / 齒輪齒排

-

聯軸器 / 免鍵式軸襯

聯軸器 / 免鍵式軸襯

-

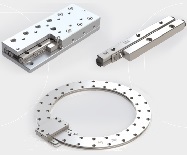

定位平台 (滑台) /

定位平台 (滑台) /

Stage / X-Y-Z Table

Theta Hybrid Hexapod

史都華平台 -

ALIO Hybrid Hexapod

ALIO Hybrid Hexapod

史都華平台 -

次系統設備(客製)

次系統設備(客製)

-

電動缸 / 千斤頂 /

電動缸 / 千斤頂 /

升降器 / 線性致動器 -

軸承 / 線性軸承 /

軸承 / 線性軸承 /

線性滑台 -

線性滑軌

線性滑軌

-

固態繼電器SSR

固態繼電器SSR

-

Karl Klein 鼓風機

Karl Klein 鼓風機

-

特殊環境用--

特殊環境用--

防爆、防水、

真空、低溫、重載 -

應用案例影片

應用案例影片

-

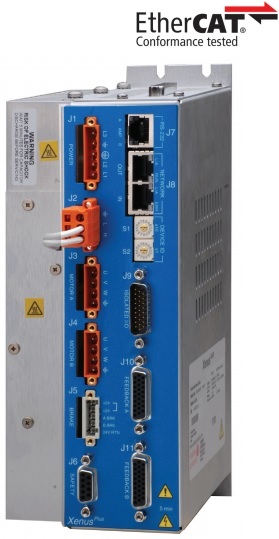

庫存出清

庫存出清

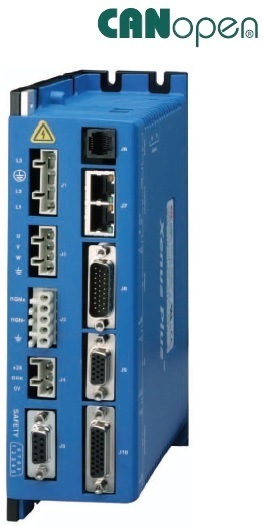

Xenus 線性伺服驅動器 AC 電源入力 (XTL、XSJ、XPL、XEL、XPC、XP2、XE2、XEC、XML、XM2、R10、R11)

|

PDF下載 |

|||||||||||

Xenus

Control Modes

• Indexer, Point-to-Point, PVT

• Camming, Gearing, Position, Velocity, Torque

Command Interface

• Stepper commands

Single-ended or Differential selectable

• CANopen

• ASCII and discrete I/O

• ±10V position/velocity/torque command

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

Communications

• CANopen

• RS232

Feedback

• Digital quad A/B encoder

• Analog sin/cos encoder (-S versions)

• Resolver (-R versions)

• Secondary encoder / emulated encoder out

• Digital Halls

I/O - Digital

• 12 inputs, 4 outputs

Accessories

• External regen resistors

• External edge filter

Dimensions: mm [in]

• 7.5 x 5.5 x 2.5 [191 x 140 x 64]

|

Model |

VAC |

IC |

IP |

|

XTL-230-18 |

100-240 |

6 |

18 |

|

XTL-230-36 |

100-240 |

12 |

36 |

|

XTL-230-40 |

100-240 |

20 |

40 |

Add -S to part numbers above for sin/cos feedback,

or add -R for resolver feedback models.

DESCRIPTION

Xenus combines CANopen networking with 100% digital control of

brushless or brush motors in an off-line powered package that can

operate from single or three-phase mains with continuous power

output to 4 kW.

Standard models use quad A/B digital encoders for feedback. Two

other versions are available for use with resolvers or sin/cos analog

encoders.

Xenus operates as a Motion Control Device under the DSP-402

protocol of the CANopen DS-301 V4.01 (EN 50325-4) application

layer. DSP-402 modes supported include: Profile Position, Profile

Velocity, Profile Torque, Interpolated Position (PVT), and Homing.

Drive commissioning is fast and simple using CME 2 software

operating under Windows® communicating with Xenus via CAN or an

RS-232 link. CAN address selection is by a 16-position rotary switch

on the front panel. If there are more than fifteen devices on a CAN

bus, the additional address bits needed can come from programmable

inputs, or can be set in flash memory. Profile Position Mode does

a complete motion index on command with S-curve acceleration &

deceleration, top speed, and distance programmable. In PVT mode,

the controller sends out a sequence of points each of which is an

increment of a larger, more complex move than a single index or

profile. The drive then uses cubic polynomial interpolation to “connect

the dots” such that the motor reaches each point (Position) at the

specified velocity (Velocity) at the prescribed time (Time).

Homing mode is configurable to work with a variety of limit,

index, and home switches such that the drive moves the motor

into a position that has an absolute reference to some part of the

machine. Eleven logic inputs are programmable as limit or home

switches, stepper/encoder pulse inputs, reset, digital torque or

velocity reference, or motor over-temperature. A twelfth input is

dedicated to the drive Enable function. Three programmable logic

outputs are for reporting a drive fault or other status indications.

A fourth optically-isolated output can drive a motor brake from

the external +24 Vdc power supply or can be programmed as a

logic output.

In addition to CANopen motion commands, Xenus can operate as

a stand-alone drive. Current and velocity modes accept ±10 Vdc

analog, digital 50% PWM or PWM/polarity inputs. In position mode

inputs can be incremental position commands from step-motor

controllers in Pulse/Direction or CW/CCW format, ±10 Vdc analog,

or A/B quadrature commands from a master-encoder. Pulse to

position ratio is programmable for electronic gearing.

Power output of the drive varies with the input power which can

range from 100 to 240 Vac, and from 47 to 63 Hz. Either single

or three phase mains can be used giving Xenus the ability to work

in the widest possible range of industrial settings. Signal and

control circuits are isolated from the high-voltage power supply

and inverter stage that connect to the mains. A +24 Vdc input

powers control circuits for keep-alive operation permitting the drive

power stage to be completely powered down without losing position

information or communications with the control system.

資料來源: https://www.copleycontrols.com/wp-content/uploads/2018/02/Xenus_CANopen-XTL-Datasheet-Datasheet.pdf

XSJ Micro Panel

Feedback VERSIONS

• Analog Sin/Cos

• Quad A/B digital

• Resolver

CONTROL MODES

• Indexer, Point-to-Point, PVT

• Camming, Gearing, Position, Velocity, Torque

COMMAND INTERFACE

• CANopen

• ASCII and discrete I/O

• Stepper commands

• ±10 Vdc position/velocity/torque command

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

• Digital inputs for indexer control

COMMUNICATIONS

• CANopen

• RS232

FEEDBACK

• Digital Quad A/B encoder

• Analog sin/cos encoder (-S versions)

• Resolver (-R versions)

• Secondary encoder / emulated encoder out

• Digital Halls

I/O - DIGITAL

• 14 inputs, 4 outputs

REGEN

• Internal

DIMENSIONS: MM [IN]

• 126 x 89 x 53 [5.0 x 3.5 x 2.1]

|

Model |

VAC |

IC |

IP |

|

XSJ-230-02 |

100-240 |

1 |

2 |

|

XSJ-230-06 |

100-240 |

3 |

6 |

|

XSJ-230-10 |

100-240 |

5 |

10 |

Add “-R” to part number for Resolver version

DESCRIPTION

Xenus Micro is a compact, AC powered servo drive for position,

velocity, and torque control of AC brushless and DC brush motors.

It operates on a distributed control network, as a stand-alone

indexing drive, or with external motion controllers.

Feedback options now include brushless resolvers in addition to

digital quad A/B and analog sin/cos incremental encoders. The

multi-mode encoder port operates as an input or output for the

feedback signals. As an input, a secondary digital quad A/B encoder

is used for dual-loop position control. Resolver and sin/cos signals

are interpolated internally with programmable resolution and appear

as digital quad A/B signals when the port functions as an output. Or,

the digital quad A/B signals are simply buffered and made available

to the system controller, eliminating cumbersome Y-cabling to share

a single encoder with drive and control system.

Indexing mode simplifies operation with PLC’s that use outputs to

select and launch indexes and inputs to read back drive status. A

single serial port on the PLC can send ASCII data to multiple drives

to change motion profiles as machine requirements change.

CAN bus operation supports Profile Position, Profile Velocity, Profile

Torque, Interpolated Position, and Homing. Up to 127 Xenus Micro

drives can operate on a single CAN bus and groups of drives can be

linked via the CAN so that they execute motion profiles together.

Operation in torque (current), velocity, and position modes with

external motion controllers is supported. Input command signals

are ±10 Vdc (torque, velocity, position), PWM/Polarity (torque,

velocity), or Step/Direction (position).

XenusPLUS

XPL

Control Modes

• Profile Position-Velocity-Torque, Interpolated Position, Homing

• Camming, Gearing

• Indexer

Command Interface

• CANopen

• ASCII and discrete I/O

• Stepper commands

• ±10V position/velocity/torque (2 inputs)

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

Communications

• CANopen DS-402

• RS-232

Feedback

Incremental

Incremental Encoders

• Digital quad A/B

Analog Sin/Cos

Panasonic Incremental A Format

• Aux. quad A/B encoder / encoder out

Absolute Encoders

• SSI, EnDat, Absolute A,

Tamagawa & Panasonic Absolute A

Sanyo Denki Absolute A, BiSS (B & C)

Resolver (-R option)

• Brushless Resolver

Other

• Digital Halls

Accessories

• External regen resistors

• External edge filter

Safe Torque Off (STO)

• Two active inputs enable power stage

• One output confirms power stage status

I/O Digital

• 15 inputs, 6 outputs

I/O Analog

• 2, 16-bit inputs

• 1, 12-bit input

• 1, 12-bit output

Dimensions: in [mm]

• 7.9 x 5.5 x 2.3 [202 x 139 x 52]

|

Model |

VAC |

IC |

IP |

|

XPL-230-18 |

100-240 |

6 |

18 |

|

XPL-230-36 |

100-240 |

12 |

36 |

|

XPL-230-40 |

100-240 |

20 |

40 |

Add -R for resolver feedback option

DESCRIPTION

Xenus Plus set new levels of performance, connectivity, and flexibility. CANopen communication

provides a widely used cost-effective industrial bus. A wide range of absolute interfaces are built-in

including EnDat, Hiperface, and BiSS.

High resolution A/D converters ensure optimal current loop performance. Both isolated and highspeed

non-isolated I/O are provided. For safety critical applications, redundant power stage enable

inputs can be employed.

XEL

Control Modes

• Cyclic Synchronous Position-Velocity-Torque (CSP, CSV, CST)

• Profile Position-Velocity-Torque, Interpolated Position, Homing

• Camming, Gearing

• Indexer

Command Interface

• CAN application layer over EtherCAT (CoE)

• ASCII and discrete I/O

• Stepper commands

• ±10V position/velocity/torque (2 inputs)

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

Communications

• EtherCAT

• RS-232

Accessories

• External regen resistors

• External edge filter

Feedback

• Digital quad A/B encoder

Analog sin/cos incremental

Panasonic Incremental A Format

• SSI, EnDat, Absolute A

Tamagawa & Panasonic Absolute A

Sanyo Denki Absolute A,

BiSS,BiSS

• Aux. encoder / encoder out

• Resolver option

• Digital Halls

Safe Torque Off (STO)

• Two active inputs enable power stage

• One output confirms power stage status

I/O Digital

• 15 inputs, 6 outputs

I/O Analog

• 2, 16-bit inputs

• 1, 12-bit input

• 1, 12-bit output

Dimensions: in [mm]

• 7.9 x 5.5 x 2.3 [202 x 139 x 52]

|

Model |

VAC |

IC |

IP |

|

XEL-230-18 |

100-240 |

6 |

18 |

|

XEL-230-36 |

100-240 |

12 |

36 |

|

XEL-230-40 |

100-240 |

20 |

40 |

Add -R for resolver feedback option.

DESCRIPTION

Xenus Plus set new levels of performance, connectivity, and flexibility. Ethernet based EtherCAT

operates in CAN application layer over EtherCAT (CoE) mode. A wide range of absolute interfaces

are built-in including EnDat, and BiSS.

High resolution A/D converters ensure optimal current loop performance. Both isolated and highspeed

non-isolated I/O are provided. For safety critical applications, redundant power stage enable

inputs can be employed.

Xenus Plus Compact CANopen XPC

CONTROL MODES

• Profile Position-Velocity-Torque, Interpolated Position, Homing

• Indexer, Point-to-Point, PVT

• Camming, Gearing

COMMAND INTERFACE

• CANopen

• ASCII and discrete I/O

• Stepper commands

• ±10V position/velocity/torque

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

COMMUNICATIONS

• CANopen

• RS-232

FEEDBACK Incremental

• Digital quad A/B encoder

• Analog sin/cos encoder

• Panasonic Incremental A

• Aux. encoder / encoder out Absolute

• SSI

• EnDat 2.1 & 2.2

• Absolute A

• Tamagawa Absolute A

• Panasonic Absolute A Format

• Sanyo Denki Absolute A

• BiSS (B&C)

Other

• Digital Halls

I/O DIGITAL

• 6 High-speed inputs

• 1 Motor over-temp input

• 4 Opto-isolated inputs

• 1 High-speed output

• 3 Opto-isolated outputs

• 1 Opto-isolated motor brake output

I/O ANALOG

• 1 Reference input, 12-bit

SAFE TORQUE OFF (STO)

• SIL 3, Category 3, PL d

DIMENSIONS: IN [MM]

• 7.54 x 4.55 x 2.13 [191.4 x 115.6 x 54.1]

|

Model |

VAC |

IC |

IP |

|

XPC-230-09 |

100-240 |

3 |

9 |

|

XPC-230-12 |

100-240 |

6 |

12 |

|

XPC-230-15 |

100-240 |

7.5 |

15 |

Add -R to the part number for resolver feedback

DESCRIPTION

XPC sets new levels of performance, connectivity, and flexibility.

CANopen communication provides a widely used cost-effective industrial bus.

A wide range of absolute encoders are supported.

High resolution A/D converters ensure optimal current loop performance.

Both isolated and high-speed non-isolated I/O are provided.

For safety critical applications, redundant power stage enable inputs can be employed.

Xenus Plus 2-Axis CANopen XP2

CONTROL MODES

• Indexer, Point-to-Point, PVT

• Camming, Gearing

• Position, Velocity, Torque

COMMAND INTERFACE

• CANopen

• ASCII and discrete I/O

• Stepper commands

• ±10V position/velocity/torque (2 inputs)

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

COMMUNICATIONS

• CANopen

• RS-232

FEEDBACK Incremental

• Digital quad A/B encoder

• Analog sin/cos encoder

• Panasonic Incremental A

• Aux. encoder / encoder out Absolute

• SSI • EnDat 2.1 & 2.2

• Absolute A

• Tamagawa Absolute A

• Panasonic Absolute A Format

• BiSS (B&C)

Other

• Digital Halls

I/O DIGITAL

• 12 High-speed inputs

• 2 Motor over-temp inputs

• 8 Opto-isolated inputs

• 5 Opto-isolated outputs

• 2 Opto-isolated motor brake outputs

I/O ANALOG

• 2 Reference inputs, 14-bit

SAFE TORQUE OFF (STO)

• SIL 3, Category 3, PL d

DIMENSIONS: IN [MM]

• 9.24 [234.7] x 5.42 [137.6] x 3.59 [91.1]

|

Model |

VAC |

IC |

IP |

|

XP2-230-20 |

100-240 |

10 |

20 |

Add -R to model number for resolver option

DESCRIPTION

XP2 sets new levels of performance, connectivity, and flexibility.

CANopen communication provides a widely used cost-effective industrial bus.

A wide range of absolute encoders are supported.

High resolution A/D converters ensure optimal current loop performance.

Both isolated and high-speed non-isolated I/O are provided.

For safety critical applications, redundant power stage enable inputs can be employed.

資料來源: https://www.copleycontrols.com/wp-content/uploads/2018/02/XP2_DS.pdf

Xenus Plus 2-Axis EtherCAT XE2

CONTROL MODES

• Indexer, Point-to-Point, PVT

• Camming, Gearing

• Position, Velocity, Torque

COMMAND INTERFACE

• CANopen application protocol over EtherCAT (CoE)

• ASCII and discrete I/O

• Stepper commands

• ±10V position/velocity/torque (2 inputs)

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

COMMUNICATIONS

• EtherCAT

• RS-232

FEEDBACK Incremental

• Digital quad A/B encoder

• Analog Sin/Cos encoder

• Panasonic Incremental A Format

• Sanyo Denki Wire-saving Incremental

• Aux. encoder / encoder out Absolute

• SSI • EnDat 2.1 & 2.2

• Absolute A

• Tamagawa Absolute A

• Panasonic Absolute A Format

• Sanyo Denki Absolute A

• BiSS (B&C)

Other

• Digital Halls

I/O DIGITAL

• 12 High-speed inputs

• 2 Motor over-temp inputs

• 8 Opto-isolated inputs

• 5 Opto-isolated outputs

• 2 Opto-isolated motor brake outputs

I/O ANALOG

• 2 Reference inputs, 14-bit

SAFE TORQUE OFF (STO)

• SIL 3, Category 3, PL d

DIMENSIONS: IN [MM]

• 9.24 x 5.42 x 3.59 [234.7 x 137.6 x 91.1]

|

Model |

VAC |

IC |

IP |

|

XE2-230-20 |

100-240 |

10 |

20 |

Add -R to model number for resolver option

DESCRIPTION

XE2 sets new levels of performance, connectivity, and flexibility.

CANopen application protocol over EtherCAT (CoE) communication provides a widely used cost-effective industrial bus.

A wide range of absolute encoders are supported.

High resolution A/D converters ensure optimal current loop erformance.

Both isolated and high-speed nonisolated I/O are provided.

For safety critical applications, redundant power stage enable inputs can be employed.

An integral fan and heatsink enable the drive to deliver the continuous output currents in any mounting orientation.

And, the internal regeneration resistor dissipates the energy returned by load decelerations.

Xenus Plus Compact EtherCAT XEC

CONTROL MODES

• Cyclic Synchronous Position-Velocity-Torque (CSP, CSV, CST)

• Profile Position-Velocity-Torque, Interpolated Position, Homing

• Indexer, Point-to-Point, PVT

• Camming, Gearing

• Position, Velocity, Torque

COMMAND INTERFACE

• CANopen application protocol over EtherCAT (CoE)

• ASCII and discrete I/O

• Stepper commands

• ±10V position/velocity/torque

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

COMMUNICATIONS

• EtherCAT

• RS-232

FEEDBACK Incremental

• Digital quad A/B encoder

• Analog sin/cos encoder

• Panasonic Incremental A

• Aux. encoder / encoder out Absolute

• SSI

• EnDat 2.1 & 2.2

• Absolute A

• Tamagawa Absolute A

• Panasonic Absolute A Format

• Sanyo Denki Absolute A

• BiSS (B&C)

Other

• Digital Halls

• Resolver (-R option)

I/O DIGITAL

• 6 High-speed inputs

• 1 Motor over-temp input

• 4 Opto-isolated inputs

• 1 High-speed output

• 3 Opto-isolated outputs

• 1 Opto-isolated motor brake output

I/O ANALOG

• 1 Reference input, 12-bit

SAFE TORQUE OFF (STO)

• SIL 3, Category 3, PL d

DIMENSIONS: IN [MM]

• 7.54 x 4.55 x 2.13 [191.4 x 115.6 x 54.1]

|

Model |

VAC |

IC |

IP |

|

XEC-230-09 |

100-240 |

3 |

9 |

|

XEC-230-12 |

100-240 |

6 |

12 |

|

XEC-230-15 |

100-240 |

7.5 |

15 |

Add -R to the part number for resolver feedback

DESCRIPTION

XEC sets new levels of performance, connectivity, and flexibility.

CANopen application protocol over EtherCAT (CoE) communication provides a widely used cost-effective industrial bus.

A wide range of absolute encoders are supported.

High resolution A/D converters ensure optimal current loop performance.

Both isolated and high-speed non-isolated I/O are provided.

For safety critical applications, redundant power stage enable inputs can be employed.

資料來源: https://www.copleycontrols.com/wp-content/uploads/2018/02/XEC-ds.pdf

Xenus Plus MACRO XML

Control Modes

• Indexer, Point-to-Point, PVT

• Camming, Gearing

• Position, Velocity, Torque

Command Interface

• MACRO

• ASCII and discrete I/O

• Stepper commands

• ±10V position/velocity/torque (2 inputs)

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

Communications

• MACRO

• RS-232

Accessories

• External regen resistors

• External edge filter

Feedback

• Digital quad A/B encoder

• EnDat, Hiperface, BiSS, SSI, & Panasonic encoders

• Aux. encoder / encoder out

• Analog sin/cos encoder

• Resolver option

• Digital Halls

Safe Torque Off (STO)

• Two active inputs enable power stage

• One output confirms power stage status

I/O Digital

• 15 inputs, 6 outputs

I/O Analog

• 2, 16 bit inputs

• 1, 12 bit input

• 1, 12 bit output

Dimensions: in [mm]

• 7.92 x 5.51 x 2.31 in (201.2 x 139.9 x 58.7 mm)

|

Model |

VAC |

IC |

IP |

|

XML-230-18 |

100-240 |

6 |

18 |

|

XML -230-36 |

100-240 |

12 |

36 |

|

XML -230-40 |

100-240 |

20 |

40 |

Add -R for resolver feedback option.

DESCRIPTION

Xenus Plus MACRO set new levels of performance, connectivity, and flexibility via the MACRO interface.

A wide range of absolute interfaces are built-in including EnDat, Hiperface, and BiSS.

High resolution A/D converters ensure optimal current loop performance.

Both isolated and highspeed non-isolated I/O are provided.

For safety critical applications, redundant power stage enable inputs can be employed.

Xenus Plus 2-Axis MACRO XM2

CONTROL MODES

• Indexer, Point-to-Point, PVT

• Camming, Gearing

• Position, Velocity, Torque

COMMAND INTERFACE

• MACRO

• ASCII and discrete I/O

• Stepper commands

• ±10V position/velocity/torque (2 inputs)

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

COMMUNICATIONS

• MACRO

• RS-232

FEEDBACK INCREMENTAL

• Digital quad A/B encoder

• Analog sin/cos encoder

• Panasonic Incremental A

• Aux. encoder / encoder out Absolute

• SSI

• EnDat 2.1 & 2.2

• Absolute A

• Tamagawa Absolute A

• Panasonic Absolute A Format

• BiSS (B&C)

Other

• Digital Halls

I/O DIGITAL

• 12 High-speed inputs

• 2 Motor over-temp inputs

• 8 Opto-isolated inputs

• 5 Opto-isolated outputs

• 2 Opto-isolated motor brake outputs

I/O ANALOG

• 2 Reference inputs, 14-bit

SAFE TORQUE OFF (STO)

• SIL 3, Category 3, PL d

DIMENSIONS: IN [MM]

• 9.24 x 5.42 x 3.59 [234.7 x 137.6 x 91.1]

|

Model |

VAC |

IC |

IP |

|

XM2-230-20 |

100-240 |

10 |

20 |

DESCRIPTION

The XM2 Xenus Plus 2-Axis MACRO is a high-performance,

AC powered drive for torque and velocity control of brushless and brush motors via MACRO (Motion And Control Ring Optical).

MACRO is a high bandwidth, nonproprietary fiber optic or wired field bus protocol for machine control networks.

Connections to a MACRO ring are via SC-type fiber optic connectors.

MACRO address selection is via two rotary switches for Master and Node addresses.

The XM2 Xenus Plus 2-Axis MACRO set new levels of performance, connectivity, and flexibility via the MACRO interface.

A wide range of absolute interfaces are built-in including EnDat, SSI, BiSS, and Absolute A.

High resolution A/D converters ensure optimal current loop performance.

Both isolated and high-speed non-isolated I/O are provided.

For safety critical applications, redundant power stage enable inputs (STO) can be employed.

In addition to the MACRO interface, torque and velocity control is also supported via an analog input with a ±10 Vdc range.

資料來源: https://www.copleycontrols.com/wp-content/uploads/2018/02/XM2_DS.pdf

Xenus R10

AFS ADVANCED FEATURE SET

• BiSS-C Unidirectional encoder, SSI (Consult factory)

• 32-bit floating point filters

• Multiple advanced filters

• Frequency analysis tools

CONTROL MODES

• Fast indexer, Point-to-Point, PVT, CSP

• Camming, Gearing, Position, Velocity, Torque

COMMAND INTERFACE

• CANopen

• ASCII Serial Binary and discrete I/O

• Stepper commands Single-ended or Differential selectable

• ±10V position/velocity/torque command

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

COMMUNICATIONS

• CANopen

• RS-232

• RS-422 (Optional)

FEEDBACK

• Digital quad A/B encoder

• Analog Sin/Cos encoder (-S versions)

• Resolver (-R versions)

• Secondary encoder / emulated encoder out

• Digital Halls

I/O - DIGITAL

• 12 inputs, 4 outputs

ACCESSORIES

• External regen resistors

• External edge filter

DIMENSIONS: mm [in]

• 192 x 142 x 65 [7.6 x 5.6 x 2.6]

|

Model |

VAC |

IC |

IP |

|

R10-230-18 |

100-240 |

6 |

18 |

|

R10 -230-36 |

100-240 |

12 |

36 |

|

R10 -230-40 |

100-240 |

20 |

40 |

Add -S to part numbers above for Sin/Cos feedback

Add -R for resolver feedback

DESCRIPTION

REV 01 below the model number on the label indicates Xenus R10 with the advanced feature set.

It is a ruggedized AC powered servo drive for position, velocity, and torque control of AC brushless and DC brush motors.

It operates on a distributed control network, as a stand-alone indexing drive, or with external motion controllers.

Indexing mode simplifies operation with PLC’s that use outputs to select and launch indexes and inputs to read back drive status.

A single serial port on the PLC can send ASCII data to multiple drives to change motion profiles as machine requirements change.

CAN bus operation supports Profile Position, Profile Velocity, Profile Torque, Interpolated Position, and Homing.

Up to 127 Xenus R10 drives can operate on a single CAN bus and groups of drives can be linked via the CAN so that they execute motion profiles together.

Operation in torque (current), velocity, and position modes with external motion controllers is supported.

Input command signals are ±10 Vdc (torque, velocity, position), PWM/Polarity (torque, velocity), or Step/Direction (position).

RUGGEDIZED STANDARDS CONFORMANCE

Ambient Temperature Non-Operating -50ºC to 85ºC

Operating -40ºC to 70ºC

Thermal Shock Operating -40ºC to 70ºC in 1 minute

Relative Humidity Non-Operating 95% non-condensing at 60ºC

Operating 95% non-condensing at 60ºC

Vibration Operating 5 Hz to 500 Hz, up to 3.85 grms

Altitude Non-Operating -400 m to 12,200 m

Operating -400 m to 5,000 m

Shock Crash Safety 75 g peak acceleration

Operating 40 g peak acceleration

MIL-STD specifications MIL-STD- 461, 704, 810, 1275, 1399

IEC specifications IEC- 60068, 60079

資料來源: https://www.copleycontrols.com/wp-content/uploads/2018/09/R10-REV01-ds.pdf

Xenus R11

FEEDBACK VERSIONS

• Analog Sin/Cos

• Quad A/B digital

• Resolver

CONTROL MODES

• Indexer, Point-to-Point, PVT

• Camming, Gearing, Position, Velocity, Torque

COMMAND INTERFACE

• CANopen

• ASCII and discrete I/O

• Stepper commands

• ±10 Vdc position/velocity/torque command

• PWM velocity/torque command

• Master encoder (Gearing/Camming)

• Digital inputs for indexer control

COMMUNICATIONS

• CANopen

• RS232

• RS-422 (optional)

FEEDBACK

• Digital Quad A/B encoder

• Analog sin/cos encoder (-S versions)

• Resolver (-R versions)

• Secondary encoder / emulated encoder out

• Digital Halls

I/O - DIGITAL

• 14 inputs, 4 outputs

REGEN

• Internal

DIMENSIONS: mm [in]

• 126 x 90 x 53 [5.0 x 3.5 x 2.1]

|

Model |

VAC |

IC |

IP |

|

R11-230-02 |

100-240 |

1 |

2 |

|

R11 -230-06 |

100-240 |

3 |

6 |

|

R11 -230-10 |

100-240 |

5 |

10 |

Add “-S” to part number for Sin/Cos version

Add “-R” for Resolver version

DESCRIPTION

Xenus R11 is a compact, ruggedized, AC powered servo drive for position, velocity,

and torque control of AC brushless and DC brush motors.

It operates on a distributed control network, as a stand-alone indexing drive, or with external motion controllers.

Indexing mode simplifies operation with PLC’s that use outputs to select and launch indexes and inputs to read back drive status.

A single serial port on the PLC can send ASCII data to multiple drives to change motion profiles as machine requirements change.

CAN bus operation supports Profile Position, Profile Velocity, Profile Torque, Interpolated Position, and Homing.

Up to 127 Xenus R11 drives can operate on a single CAN bus and groups of drives can be linked via the CAN so that they execute motion profiles together.

Operation in torque (current), velocity, and position modes with external motion controllers is supported.

Input command signals are ±10 Vdc (torque, velocity, position), PWM/Polarity (torque, velocity), or Step/Direction (position).

RUGGEDIZED STANDARDS CONFORMANCE

Ambient Temperature Non-Operating -50ºC to 85ºC

Operating -40ºC to 70ºC

Thermal Shock Operating -40ºC to 70ºC in 1 minute

Relative Humidity Non-Operating 95% non-condensing at 60ºC

Operating 95% non-condensing at 60ºC

Vibration Operating 5 Hz to 500 Hz, up to 3.85 grms

Altitude Non-Operating -400 m to 12,200 m

Operating -400 m to 5,000 m

Shock Crash Safety 75 g peak acceleration

Operating 40 g peak acceleration

MIL-STD specifications MIL-STD- 461, 704, 810, 1275, 1399

IEC specifications IEC- 60068, 60079